Full power with a free back – power from both sides

Bifacial solar modules use light from both sides, significantly increasing energy yield. Read this article to find out where this technology is particularly effective and how Megasol optimally coordinates such modules and their substructures.

Anyone familiar with solar cells knows that they are made up of two layers of silicon. When sunlight hits them, the radiation sets electrons in motion, generating electricity. It does not matter which side the light hits the silicon from.

In everyday life, we usually see solar modules on roofs or facades, permanently mounted and facing the sun. No wonder, then, that many people assume that modules only utilise light from one side. However, there are also so-called bifacial modules, which are installed at a distance from the ground and utilise the incoming light from both sides. They convert not only direct sunlight into energy, but also reflected radiation, for example from light-coloured ground, snow-covered surfaces or neighbouring buildings.

The reflectivity of the ground surface – known as the albedo value – is decisive for the additional yield of bifacial modules. It describes how much light a surface reflects diffusely. Light-coloured materials such as fresh snow (albedo 0.80–0.90), clean concrete (approx. 0.30) or sandy soil reflect particularly strongly, while dark surfaces such as asphalt (0.15) contribute hardly any backlighting. An average albedo value of 0.20 is assumed for the Swiss Plateau, while in alpine regions in winter it is calculated at 0.80. These high reflection values in the mountains explain why bifacial modules are particularly effective there – especially in the winter months, when the sun is low in the sky and there is snow on the ground.

Depending on the location and substrate, this can result in 5 to 35 percent additional yield from the same area. Systems in open spaces, in alpine regions or as part of photovoltaic applications in agriculture (agri-PV) benefit particularly strongly. With the growing demand for winter electricity and the targeted development of such areas, bifacial solutions are increasingly coming into focus.

Megasol is one of the pioneers of this development. The Swiss company was quick to bring bifacial modules to market and takes a holistic approach to the technology. From the cell to the module to the appropriate substructure, everything is designed for maximum light yield.

‘Megasol is one of the few manufacturers that not only develops solar modules, but also the appropriate mounting systems. This ensures that no wattage is lost due to unnecessary shading.’

Daniel Sägesser, CCO

How bifacial solar modules get more out of the light

Bifacial modules consist of the same solar cells as conventional ones. The difference lies in the design of the beam and protective layer. Since both sides are translucent, photons can enter the cell from above and below. The result: more electricity generated from the same area.

The bifaciality factor shows how well this works. It indicates how much power the rear side generates compared to the front side. ‘Our modules consistently achieve over 90 percent,’ says Daniel Sägesser, member of the management board at Megasol. ‘That's a top value. Today, 60 to 90 percent is more common.’ In concrete terms, this means that in tests under the same conditions, the rear side delivers almost as much electricity as the front side.

One key to this lies in the glass-glass structure that Megasol has been using as standard for a long time. ‘We deliberately avoid using light-tight back sheets,’ says Sägesser. ‘Glass on both sides allows more light to reach the solar cell and also protects it permanently.’

Depending on the application, the rear glass can also be tinted – for better internal light diffusion or for design purposes. Sägesser highlights partial printing as a special feature: "We only print on the grid between the solar cells. The rear surfaces behind the solar cells remain translucent, and the module still appears uniformly bright.‘ This design offers great flexibility: ’Installers have several options with a single module type, whether classic or bifacial mounting."

Modules and substructure perfectly matched

With bifacial solar systems, it is not only the module that determines the yield – the substructure also plays a key role. This is because parts that shade the rear side reduce the additional yield. ‘Megasol is one of the few manufacturers that not only develops solar modules but also matching mounting systems,’ explains Daniel Sägesser. ‘With bifacial systems in particular, it is important that everything from the mounting system to the cable routing is coordinated.’

One example of this is the Wingport system: a robust steel construction for carports. Together with NICER modules, it forms a dense, weatherproof roof covering, but still allows the light reflected from the ground to reach the rear of the modules unhindered.

Megasol also offers optimised solutions for open-space installations: tracker systems that align themselves with the sun throughout the day. Their design specifically avoids rear shading, ensuring a consistently high yield.

Where bifacial PV modules are particularly effective

Bifacial modules are particularly worthwhile where the rear side receives sufficient light through reflection from the ground or diffuse radiation. Bright surfaces, sufficient distance from the ground and as little shading as possible are crucial.

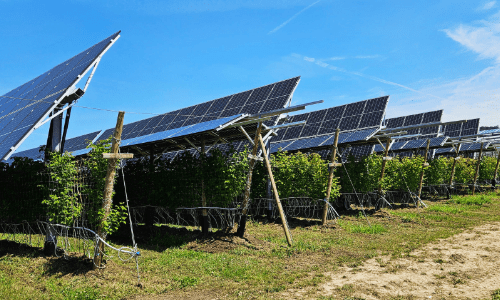

Agri-PV system with bifacial modules: simultaneous use of land for agriculture and electricity production.

Open space installations and Agri-PV

Agri-PV solar modules enable the simultaneous use of land for energy generation and agriculture, such as crop cultivation or grazing. Bifacial modules achieve additional yields of 10 to over 25 per cent, and even up to 35 per cent in snowy conditions.

Elegant power supplier: Wingport protects vehicles and generates clean energy at the same time.

Carports and canopies

They are also ideal for use on carports, bicycle parking spaces or canopies covering entire paths. Light-coloured slabs or concrete surfaces reflect a lot of sunlight. In combination with suitable mounting systems, additional yields of up to 25% are possible here.

The compact solar cable system (KSS) is an innovative solution that has been specially developed for use in alpine regions.

Alpine locations

In mountainous regions, snow surfaces achieve reflectance values (albedo) of over 80 per cent. The additional winter electricity can help to close supply gaps. Megasol is involved in several alpine installations, where it is testing new systems for vertical mounting, such as tensioned cable structures.

The horizontally arranged, translucent modules generate sustainable energy. | Picture: Tresolar AG

Building integration

Facades, railings and solar fences also benefit from bifacial technology, not only technically but also in terms of design. Modules with partial printing can be harmoniously integrated into buildings while still utilising the rear radiation.

Where it's not worth it

It makes little sense to use them where the rear side is permanently in the shade – for example, modules mounted directly on tiles or in densely built-up areas with no light from below.

What planners and installers should bear in mind

In many cases, the use of bifacial modules is obvious – for example, in the applications mentioned above. For other projects, such as those on flat roofs, careful consideration must be given to the balance between land use and potential additional yield.

To effectively expose the rear side, modules must be mounted at a greater distance apart. Although this reduces the power density on the front side, it is more than offset by the additional yield. Most planning tools take this effect into account.

‘For more complex systems, we offer project-specific yield analyses,’ says Daniel Sägesser. ‘This allows planners and installers to assess at an early stage whether the additional yield from bifacial panels is also economically viable.’

Several factors must be considered for bifacial optimisation:

- Angle of installation and mounting height: Bifacial modules are usually installed at a slightly steeper angle than monofacial modules.

- Row spacing: Greater spacing promotes light incidence on the rear side.

- Albedo: The reflectance of the ground surface directly influences the additional yield.

- System components: Higher currents affect cables, inverters and protective devices. All direct current components must be dimensioned accordingly.

Bifacial modules open up new possibilities in system planning – both technically and economically. Those who understand the conditions and set up the system correctly can get significantly more out of solar radiation.